IoT-Based Analytics and Production Monitoring for the Industry 4.0.

IndustrialSpyder™ is an innovative, flexible, and integrated platform for industrial analytics and serves as a backbone for the enterprise digitalization journey. Establishing a robust high-performance data integration of a wide variety of data sources and subscribers in an industrial environment and a dedicated storage layer establishes a foundation for digitalization projects.

As an integrated real-time production monitoring system, IndustrialSpyder™ enables monitoring signals from machines and monitoring the movements of employees and tools in the production hall. It translates signals into events with the help of the IoT (Internet of Things) technology and converges events into a central platform that is scalable and durable, thus enabling the transfer of substantial amounts of data.

IndustrialSpyderTM is designed for a wide range of individuals working in industrial environments. It is used by employees at machines and stations, shift managers, internal IT (Information Technology) managers, and C-level management.

Benefits of using the IndustrialSpyder™

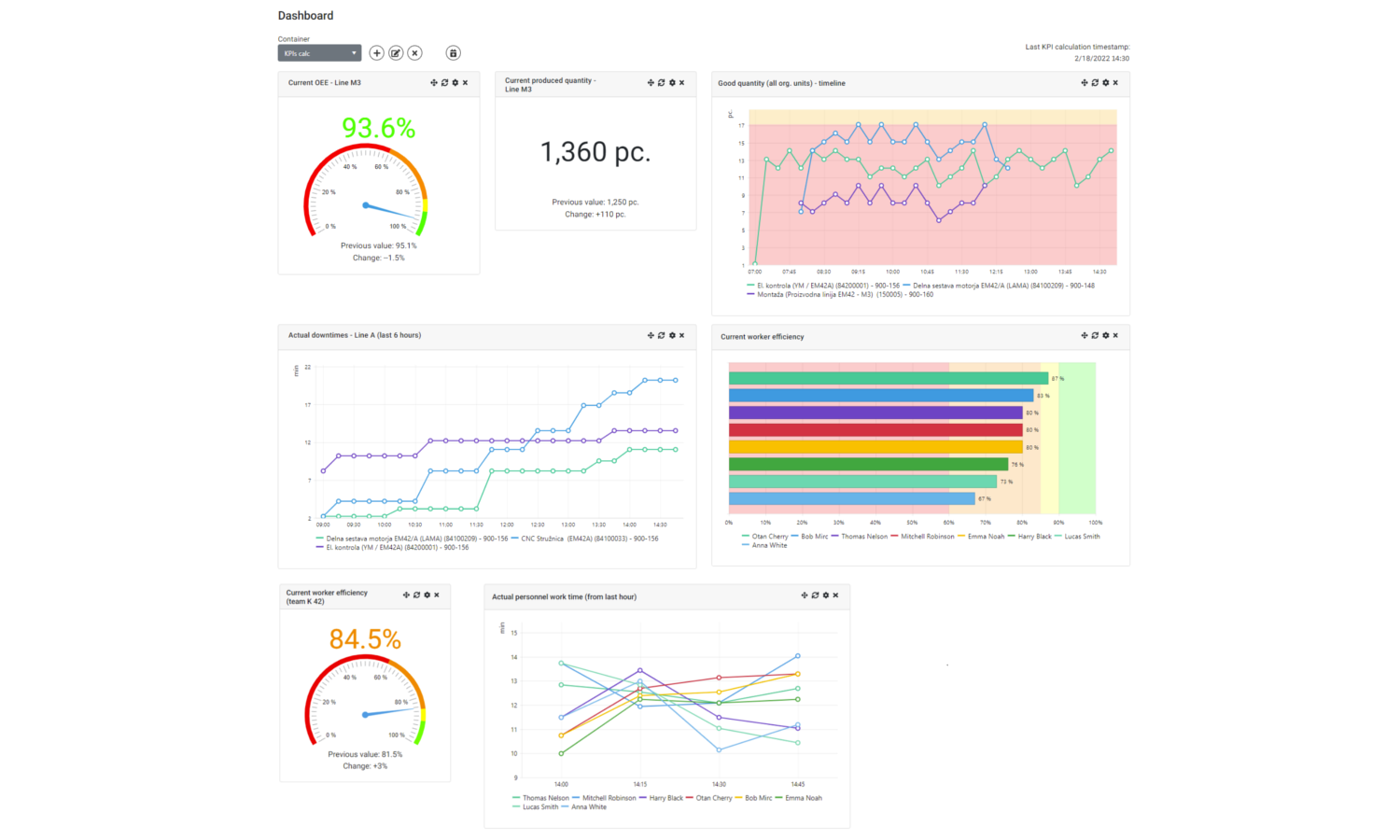

Readily available, real-time status and information provided by IndustrialSpyderTM enables immediate action. Additionally, identification and addressing the areas of potential efficiency improvement by measuring various KPIs can help you make informed decisions.

No matter what industry we are talking about, the biggest beneficiaries of IndustrialSpyderTM are typically the floor managers, maintenance managers, and production managers. The solution brings them the following benefits:

- Better control over the entire production line

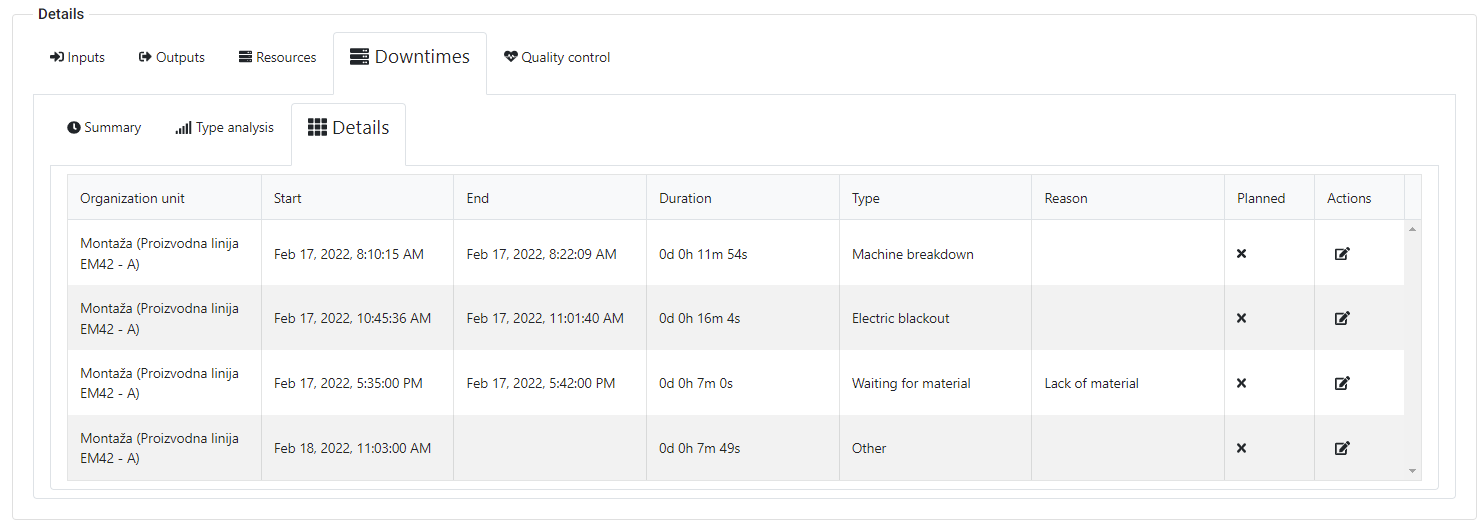

- Reduction (or faster resolution) of downtimes

- Optimization of maintenance duration

- Dashboard personalization

- Improved measurement of worker productivity during the shift

- Improved control over skills needed to operate machines and thus reducing workplace accidents and/or damage to the machines

- The solution follows industry 4.0 guidelines

How does the IndustrialSpyder™ work?

The customer’s production line is our focus. We can measure and analyze an unlimited number of parameters that one can collect from an industrial environment using the readily-available measurement technology. And we put them all under a single pane to enable stakeholders’ convenient access to relevant and complete information.

Integrations and Partner Network

Through our partner network, we can cover a broad set of measurement tools and probes out of the box and integrate the collected data. At the same time, we can also onboard new technology into our solution should that be crucial for a specific type of customer.

The product can be integrated with the current systems used in the company (for example with the SAP system, Špica system, etc.), and the data is additionally secured with blockchain technology.

Getting the data

How do we collect the data? There are many sources (or data connectors) we count on, the most common being the following:

- MES, ERP (SAP)

- Machine logs / Databases (SCADA)

- IoT system

- LAN gateways for legacy, analog machines

- Resource position monitoring (presence of workers at work posts, logistic moves, etc.)

To successfully collect the data and process the customers’ streams in our solution, we are using the enterprise MQ bus based on Kafka. It allows high data volume and frequency. The technology is scalable and robust at the same time, which makes the investment future-proof.

Using the Platform – From Data to Information

The exact information provided depends on the actual environment and customer needs. There are some typical KPIs provided, but then again, the customer might have specific ones that can also be provided through customization of the overall system. Plenty of information can be provided based on the collected data.

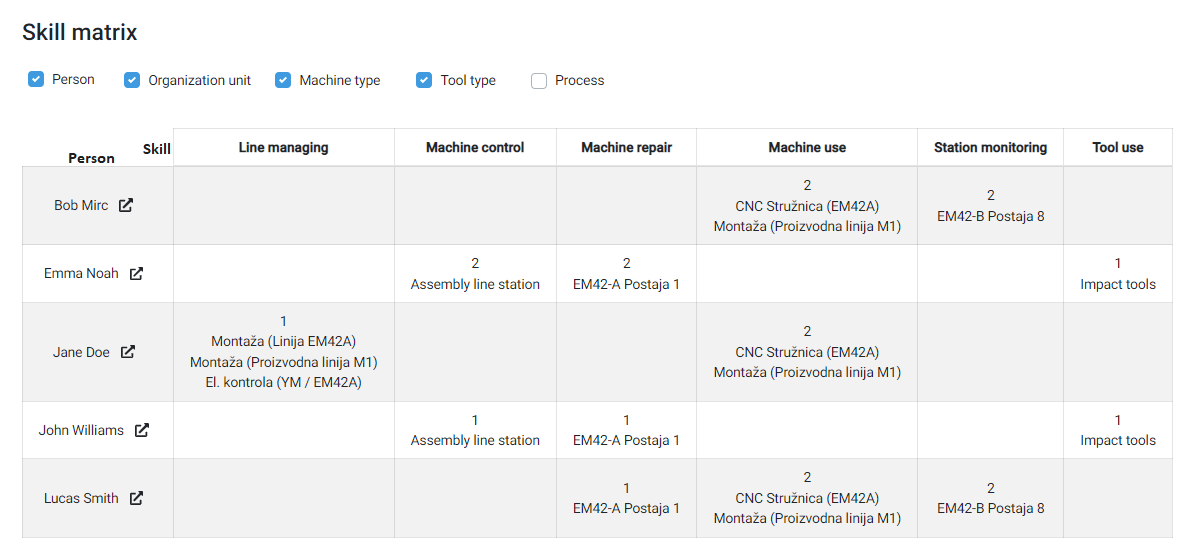

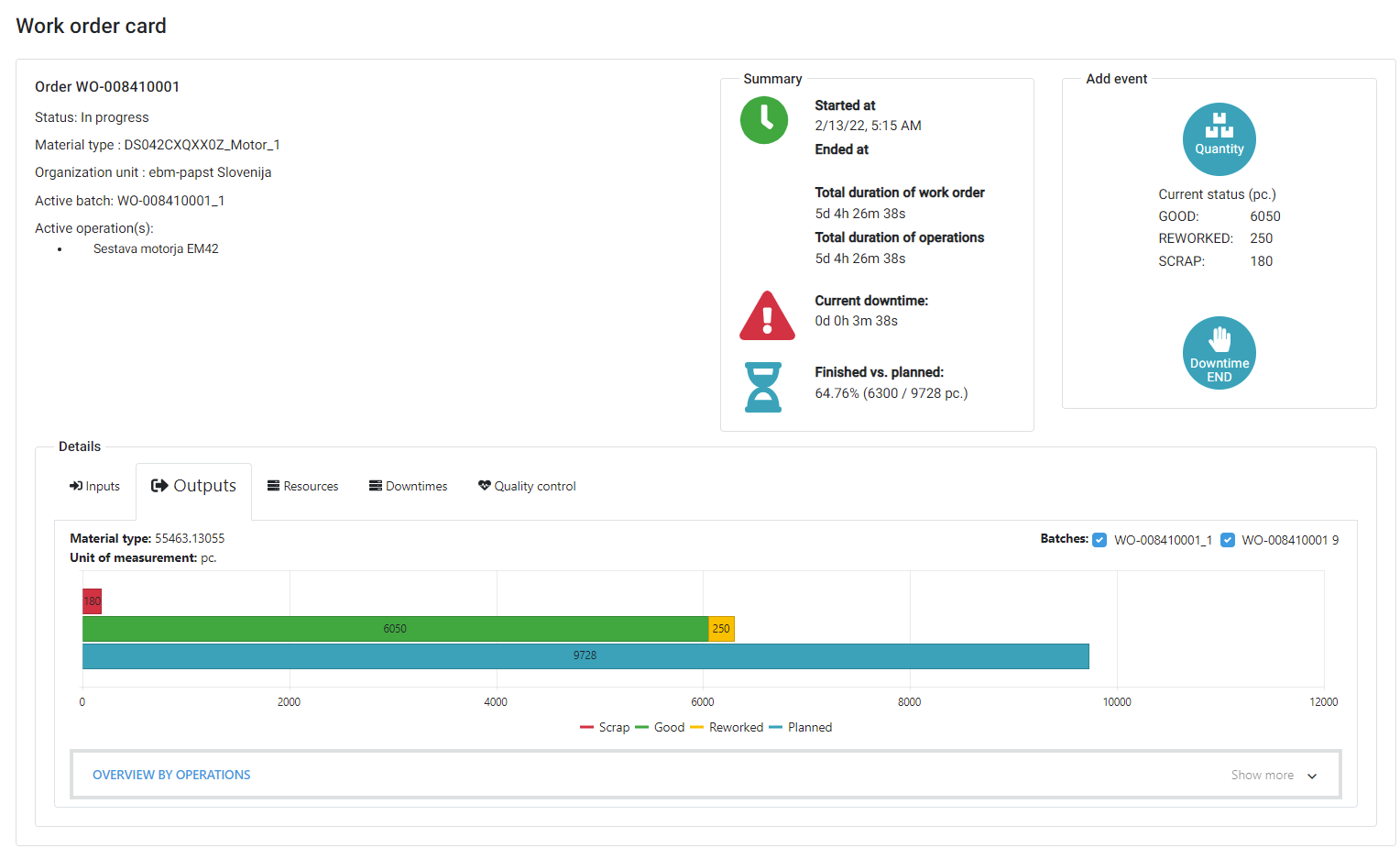

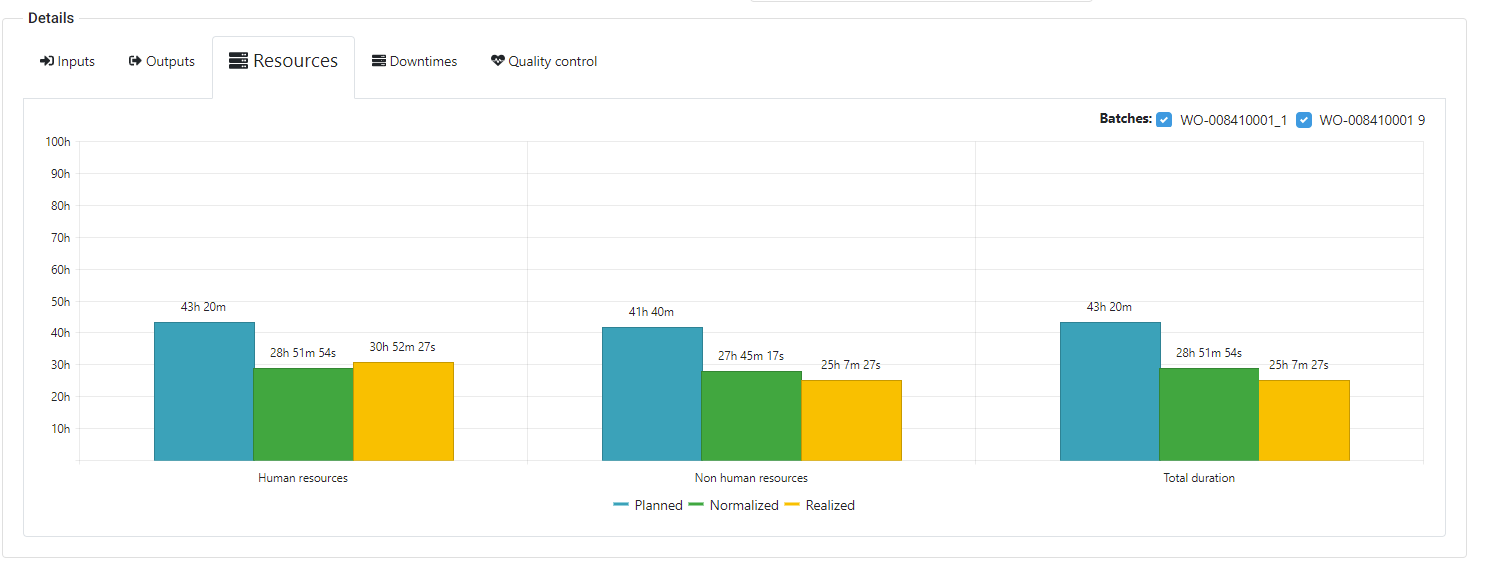

Some of it is quite common, such as real-time shop-floor information about resource status, analytical metrics (ISO 22400 KPIs: OEE, TPM, SMED), system of alerts, etc. Once the data is there, we can also provide in-depth analytics of historical activity along with the most common production-related KPIs: OEE, TPM, SMED, HR skills matrix/efficiency, and more.

Additional extensions are available to make the measured KPIs even more business-relevant:

- Integration of external parties (suppliers…)

- Planning optimal HR teams

- Optimization of planning/scheduling

- Predictive analytics (quality, maintenance…)

You don’t need to monitor people on the shop floor? No problem, we then continue with the implementation of Industrial Spyder only on machines and tools.

About NIL-u & Analitica

NIL is a globally recognized provider of advanced data center, network, cloud, cybersecurity solutions as well as services for business and industry environments, state institutions, and public organizations. With its efficient solutions, NIL helps organizations become more successful in the digitalized world. The headquarters are in Ljubljana, Slovenia. NIL employs more than 180 experts and is part of the Danish Conscia Group.

Analitica is a software development and consulting company that combines expert knowledge from the fields of natural sciences and engineering with in-depth knowledge of information technology. At Analitica, we believe that in complex environments, IT projects demand in-depth expertise of the fields covered by each project.

Ministrstvo za gospodarski razvoj in tehnologijo RS

Evropska Unija Evropski sklad za regionalni razvoj